HS248C

HS248C is 48 inches with single carriage double systems single roller. 5.0 inches motorized min carriage, excellent performance, stable quality, higher efficiency, the efficiency increases by 40% compares to the existing models in the market. Single carriage dual-system, equipped with 16 yarn feeders, up-position rollers, high-performance sinker, dynamic density, motor control reversing carriage, motor control needle transfer, motor control tuck, take-down device, two sets of scissors and clip.

HS248C uses digital technology, high-speed and efficient, to achieve pointel, tuck, jacquard, intarsia, apparent shape, hidden shape, the other irregular patterns. Suitable for wool, cashmere, cotton, chemical fiber, silk and all kinds of blended yarn, the production of sweaters, scarves, gloves, hats and knitted apparel accessories.

HIGHLIGHT

• 5.0 inches intelligent encoder motorized mini carriage, Self-Correcting, more efficient, more stable.

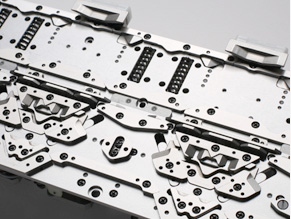

• Imported SK5,SKD11 steel materials, Japanese imported equipment, advanced processing technology, ensures the precision of needle bed and cam, to solve the various problems of knitting and needle transfer, improves machine knitting range and reliability, extends machine life.

• HT300 iron casting frame is treated by heat and eliminates internal stress and stabilize the machine life.

• Force loop-off technology avoids stitch missing problem.

• Take down force is more even, fabric density is more stable, more smoothly to gentle pulling.

• Double-side narrowing, high speed and high efficiency, 1.7m/s, more than 40% production efficiency is promoted than previous generation.

• Non-waste yarn with comb, scissors and clip to promote production efficiency, reduce waste yarn, save labor cost.

• Dynamic density, adjustable density in a single row, more various patterns.

• Zero waiting of racking, needle transfer and knit is synchronous, more efficient.

• Automatic oiling system of needle bed, reduce wear and extend machine life.

• Networking features is useful for large-scale production online management, mobile App supports offsite management.

|  |  |

Touch Screen One-touch screen, easy operation, satisfied experience. | Needle Bed Divided structure, steel sheet made from import high quality steel precisely punched and fine polished to reduce the resistance with needles and increase the longevity. | Cam Core spare parts, imported steel, manufactured by high-speed CNC. Fine polishing to achieve surface finish as mirror to reduce the resistance with needles and improve efficiency. |

|  |  |

Scissors And Clippers Clippers work with scissors to increase the knitting efficiency. | Take Down Comb Use motive release technology, work with clippers and scissors set to decrease the waste yarn, yarn clearing work and increase the productivity. | Positive Yarn Provider Positive yarn providing, successfully reduce yarn resistance, increase knitting efficiency. |