•三系统5.2英寸电机款小机头,高速回转,运行效率提升15-20%。

•编织宽度52寸,总针数728枚,适合做单片或双片精品鞋面。

•无废纱起底,免拆片,节约废纱成本和人工成本,提高效益。

•局部填充,增强鞋面立体效果,为设计带来更多可能性。

•紧编、紧吊目可调;鼓波、铲针、挑孔稳定性高,废片率低。

•滑屏触控,操作更流畅。

•自动加油装置,定时定量润滑,更好维护,减少机件磨损,延长机器寿命。

•联网功能有利于大规模生产在线管理,手机APP支持异地管理。

• 2680*878*2010mm , 净重970公斤,功率2.0KW。

|  |  |

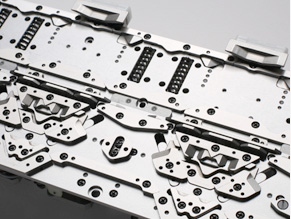

显示屏 采用全触摸屏.方便客户操作.提高客户应用体验。 | 针扳 分体设计.与针磨合部分的插片采用进口钢材经精冲与 研磨制造而成.破少与针脚的磨损降低针脚阻力.有效提 高了机器编织效率。 | 三角 编织核心部件.应用进口钢材,采用高速加工中心制造 而成.并且经过研磨使得表面光洁度接近镜面光洁,有 效减少与针脚磨损,提高机器编织效率。 |

|  |  |

剪刀夹子 夹子与剪刀相互配合.提高编织效率。 | 起底针板 采用活动释放原理.与剪刀夹子配合.有效减少纱线浪费 减少人工拆片。 | 滚筒输纱器 积极送纱.有效减少纱线阻力.提高编织效率。 |

Machine Model | HF352S (52 inches three systems single roller) | HF338S (38 inches three systems single roller) | |||

Gauge | 14G | 14G | |||

Needles/Width | 728 needles/52 inches | 532 needles/38 inches | |||

Main Function | fullfil basic pattern (half milano, full needle, single face and so on) irregular multi-colors jacquard, intarsia, cable, pointel and so on, also can fulfil tight tuck pattern as well as filling pattern. | ||||

T E C H N I C A L S P E C I F I C A I O N | KnittingSystem | Single carriage three systems, with digital technology, fulfil patterns of transfer, pointel, tuck, intarsia, jacquard, double jersey plain, apparent shape, hidden shape and other regular pattern knitting functions. | |||

Knitting Speed | Max knitting speed 1.7M/S. 32 speed sections controlled by servo motor. | ||||

Stitch Density | 64 density selection range 0-650 controlled by stepping motor, electrical fine adjust technology. | ||||

Dynamic Stitch | Deviced by dynamic stitch technology, achieve the variety stitches in one course and variety density in one course to improve knitting efficiency and variety. | ||||

Rib transfer | Free transfer double ways between front and back needle at same time and no limitation by carriage movement. Transfer and knit individually. | ||||

Sinker | Stepping motor control the adjustable sinker to achieve the multiple shaping and widening function. | ||||

Selection Needles | 8 sections selection needles | ||||

Single Packing | Motor drive racking, achieve 1/2 or 1/4 needle racking at any position. max 2 inches one side suitable for 14G machine. | ||||

Turn Back Joint(Optional) | Turn back joint controlled by stepping motor increase the carriage return speed and productivity as well as avoid the worn of the carriage rail. | ||||

Roller Device | Up-position roller can fuifil the perfect take down of fabric and the tension requirement for partial knitting. | ||||

Yarn Roller | Positive yarn roller precisely control the tension of the yarn to guarantee the fabric quality. | ||||

Yarn Carrier | 2*8 yarn carriers deviced on 4 double sides lead rail. | ||||

Safety | Full machine cover to reduce the noise ad dust. Cover sensor,urgent button,power off device and indicator to guarantee the safety. | ||||

Auto Stop | Machine auto stop when yarn break, yarn joint stuck, fabric roll inside, needle hit, overload, program error and program end happens. | ||||

Needle Detector | Detect the floating needle to avoid the needle hit. This deviced with smart program and infrared sensor only detect the knitting area to avoid the miss alarming. | ||||

Computer System | LCD monitor, touch screen, graphical interface, USB and net input, 1GB RAM for big file storage. Monitor: Working data, stitch data optical and adjustable during production for convenient operation. Program system and machine computer system easy to update and support CNT/HCD/OOO pattern file. Multiple system language operation includes Chinese, English and other languages. | ||||

File Input | USB and network | ||||

Power Off Memory | Deviced advanced CMOS technology, when power off happen the knitting data and file is saved for restart knitting. | ||||

Net Connection | High speed (ETHERNET), maximum connect 254 machines for file input to fulfil monitor and data sharing. | ||||

Dimension | L*W*H 2325*920*2010mm L*W*H 2325*920*2010mm | ||||

Weight | 970kg 890kg | ||||